CLIMATE NEUTRALITY BY 2050

Glass Fibre Europe supports the European Green Deal and the European Union’s objective to become climate neutral by 2050. The industry’s contribution to this objective will be two-fold:

On one-hand, the industry will continue manufacturing and developing new products and solutions, enabling the transition in key sectors of the economy. Find more (here) about the contribution of our products to the carbon neutrality objective.

On the other hand, the glass fibre industry will continue reducing the carbon footprint of the products it manufactures – for instance by developing new technologies. Discover below how the European industry reduced its total direct emissions by 1/3 since 2005 and the challenges ahead.

The glass fibre industry has the ambition to become climate neutral by 2050. The coming challenges ahead are manifold, with only two investment cycles left for its furnaces and an enabling framework still to be deployed. Access to sufficiently available and competitive carbon neutral energy, development of relevant infrastructure, effective protection against unfair trade practices as well as new market opportunities related to sustainable products, are key conditions to ensure the industry stays globally competitive during the transition.

1/3 reduction in total direct emissions since 2005

Since 2005, the continuous filament glass fibre sector has reduced its total direct emissions by one third (source: reported emissions in European Union Transaction Log (EUTL, 2022)). This is a remarkable achievement considering the fact that a quarter of the sector’s emissions are ‘process emissions’ which cannot be reduced by a reduction in energy demand or a switch to alternative energy sources.

The industry implemented several measures in its manufacturing sites that contributed to an estimated reduction in CO2 emissions of over 200kt/CO2 per year during the same period (source: reported emissions in European Union Transaction Log (EUTL). These measures to reduce the manufacturing emissions can be classified in 5 main fields of actions.

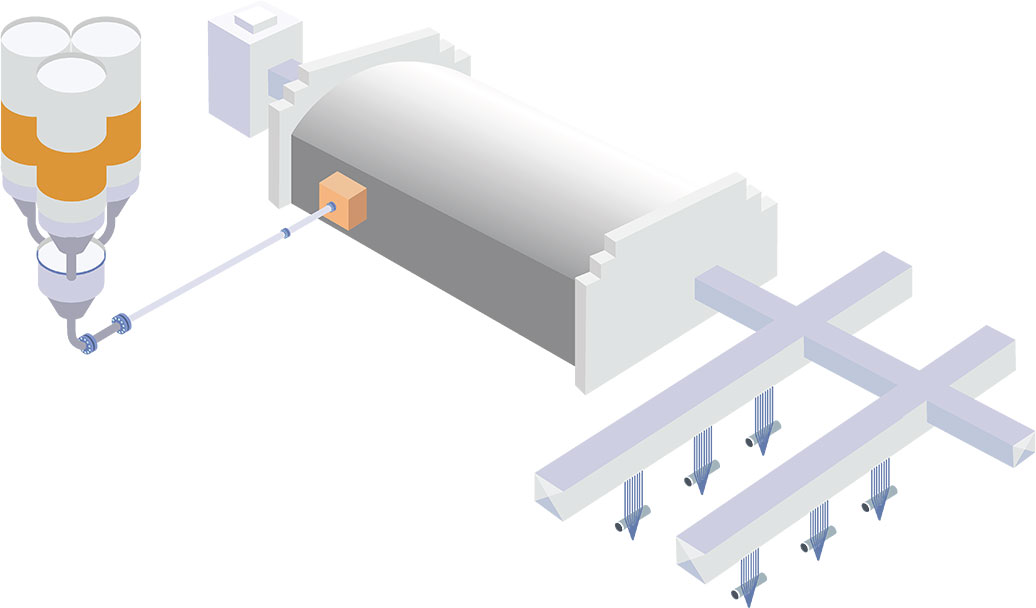

Raw material

Furnace

Melting process

Energy

Bushing

The Challenges Ahead

Achieving carbon neutrality in the industry is a monumental challenge. To be carbon neutral, the glass fibre industry will have to overcome in the next two decades two major technology hurdles: 1°) the current absence of technology ready options for switching to carbon neutral energy and 2°) the significant share of ‘process emissions’ in the total emissions which cannot be reduced by an energy switch.

The glass fibre industry is taking up the challenge, and it has identified 4 potential routes for further reducing its manufacturing emissions in the coming decades. Turning these potentials into options is going to require tremendous efforts from the industry and an unprecedented transformation of the European Union as a whole. The categories below describe the potential routes identified by the glass fibre industry, the barriers to overcome, and actions required to activate these routes.

Circular Economy

Description

Further recycling of internal waste fibres

(maximum reduction potential -3% direct emissions)

Obstacles

The potential for emission reduction is limited by the availability of waste fibres. Only non-contaminated glass fibres with the same composition (not recycled bottles or windows) can be reused in the furnace.

Actions

The glass fibre industry is working on further reducing its waste with a zero waste to landfill objective. (Discover here)

Circular Economy

Optimisation

Description

Optimisation with further uptake of best available technologies, increase in capacity and reduction in forehearth size

(maximum reduction potential -15% direct emissions)

Obstacles

The industry is characterised by a high uptake of best available technologies. Since the best technologies are already widely used in the European industry, their potential for reducing the emissions is limited. In some cases, the uptake of technologies or options are limited by some factors such as space limitations or availability of certainenergy sources or raw materials.

Actions

The industry always assesses on a case-by-case basis the possibilities to install the best available technologies in its installations. Although significant, the incremental improvement listed here will not be sufficient to achieve the carbon neutrality objective. Breakthroughs in technology will be needed.

Optimisation

Energy Switch

Description

Switch to carbon neutral energy; i.e. electric melting, hydrogen, carbon neutral gas, liquid biofuel

(maximum reduction potential -85% direct emissions)

Obstacles

The technologies are not yet mature enough to fully switch to a carbon neutral energy source but for biogas (biomethane in particular). However, this last option is not viable considering the limited production levels in Europe. Next to the technology readiness, another major obstacle today is the access to abundant and competitive alternative fuels.

Actions

The industry is working on developing technologies for switching to carbon neutral energy. The development and deployment of these technologies requires financial support, and infrastructures to make the alternative energy sources available in sufficient quality and quantity at a competitive price.

Energy Switch

Carbon Capture

Description

Carbon capture and storage

(maximum reduction potential -90% direct emissions)

Obstacles

Carbon capture is the category with the highest theoretical potential, but with structural barriers that are hard to address. These limits include: the space limitations in the installations, the low CO2 volumes and concentration in the industry, the absence of infrastructures, the low market demand for the use and low public acceptance for the storage.

Actions

Should the authorities decide to pursue this route, an extensive transport and storage network would have to be deployed.

Carbon Capture